Machine for packing the smallest Tubes

The Technology

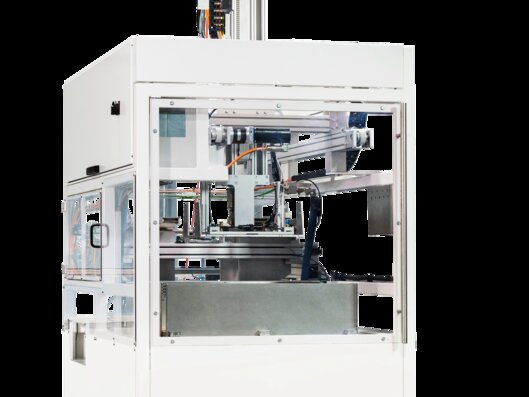

Compact and smart packing

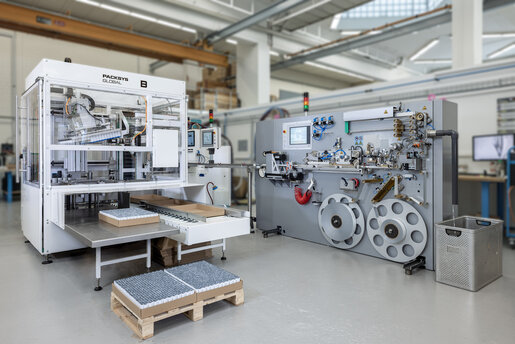

The highly efficient and reliable MiniMaster tube packing machine can be fully integrated in the Mini 120 Line.

The solution is suitable for tube diameters from 10 to 22 mm (up to 25mm for extruded tubes) and can run with a speed of up to 120 tpm. The Mini 120 and MiniMaster together require only 15 m2.

Box transport and filling unit

The box transport system is a box driven infeed roller conveyor with adjustable guide rails according to the packing regulations. It is equipped with a pneumatic box separating and pushing unit as well as a motorized box lifting unit for tube length adjustment. The box holding unit portrait and landscape have spindles which can be adjustment by hand with manual display. The spreading sheets can be used from any packing machine.

Your Benefits

- Completes the Mini 120 line

- High line efficiency

- Improved hygiene, no need for product to be manually handled

- Reduction in required number of operators allows better social distancing

- Simple and efficient operation

- Smart design with a small footprint

- Fast and user-friendly tooling change

- Reproducibility for high process reliability in automatic unpacking at filling machine

- Less labour costs resulting in increased ROI

MiniMaster Machine Details

Closed Process

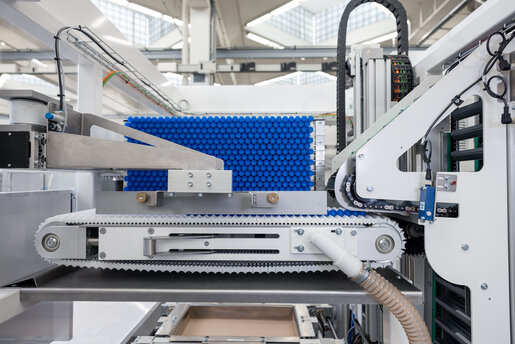

The tubes are taken automatically from the Mini 120 and transferred to a bucket conveyor system which transports the tubes into the MiniMaster. When the bucket conveyor transfers the tubes to the patented grouping belt, the transfer process eliminates any gaps so that each box is 100% filled with tubes. When the number of tubes for each row is reached, the grouping belt stops and the grouping pusher pushes each row of tubes onto the mandrel plate. During this time the MiniMaster’s small (38 tube) accumulator fills up and then accelerates to temporarily run faster than 120 tpm (grouping process), thereby emptying the accumulator. This process is repeated until the mandrel plate is full. When the mandrel plate is full, it is then driven up and tilted 90° and lowered into the waiting box, where the tubes are stripped off the tubes after which the empty mandrel plate returns to the loading position. The complete box transport process takes approximately 6 seconds. Finally, the filled box is ejected onto the unloading table which is about 500 mm height from the ground. The box handling runs independently.

Grouping area

The grouping belt is equipped with a quick-change function. A height adjustment when changing tube diameter is no longer needed because of tube range and the new design of the new grouping belt shells.

The grouping pusher motor is controlled and monitored. This is new with a pneumatic blocking monitoring instead of a spring and limit switch.

The mandrel plate from CoreMaster or FlexMaster packing machines can be used if the plate size is in the range of 280 mm to 600 mm.

Software and operation

The operation of the MiniMaster is easily visible and controlled by a 22” screen.

MiniMaster Video

MiniMaster Technical Data

| Infeed/Outfeed | Straight in, straight out |

| Weight | approx. 1,400 kg |

| Speed | up to 120 tubes/minute |

| Ø range | 10 – 22 mm (25 mm for extruded tubes) |

| Tube length | 40 - 175 mm incl. cap |

| Tube style | Round and top-heavy tubes are both possible |

| Box dimensions |

(L × W × H) Min. 280 x 280 x 65 mm |

| Plastic bag possible | Yes |

| Special packing style | Draxis, folding box (portray/landscape) |