Twin Decorator systems reduces print changeover to just 5 minutes

08 Jul 2015

Pivotal development for the can manufacturing industry

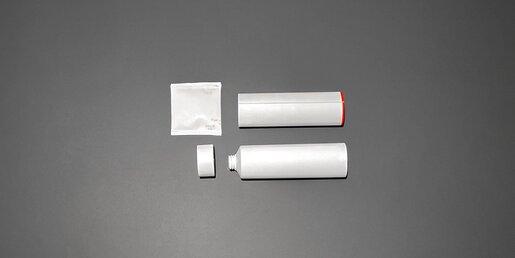

The aluminum tube and monobloc aerosol can industries are confronted by decreasing “batch sizes” down to 25,000 units or less. Small batch sizes are challenging as each batch requires a set-up of the printing machine (and often no other machine in the line). Printer changeover times, depending on the skill/experience of the operator and the complexity of the changeover, may take as much as 3-4 hours. The pressure on operators to start producing often leads to scrap, and the idling of other machines during the print changeover.

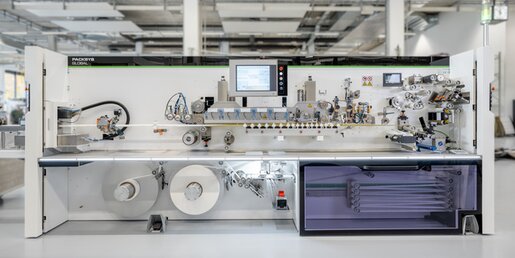

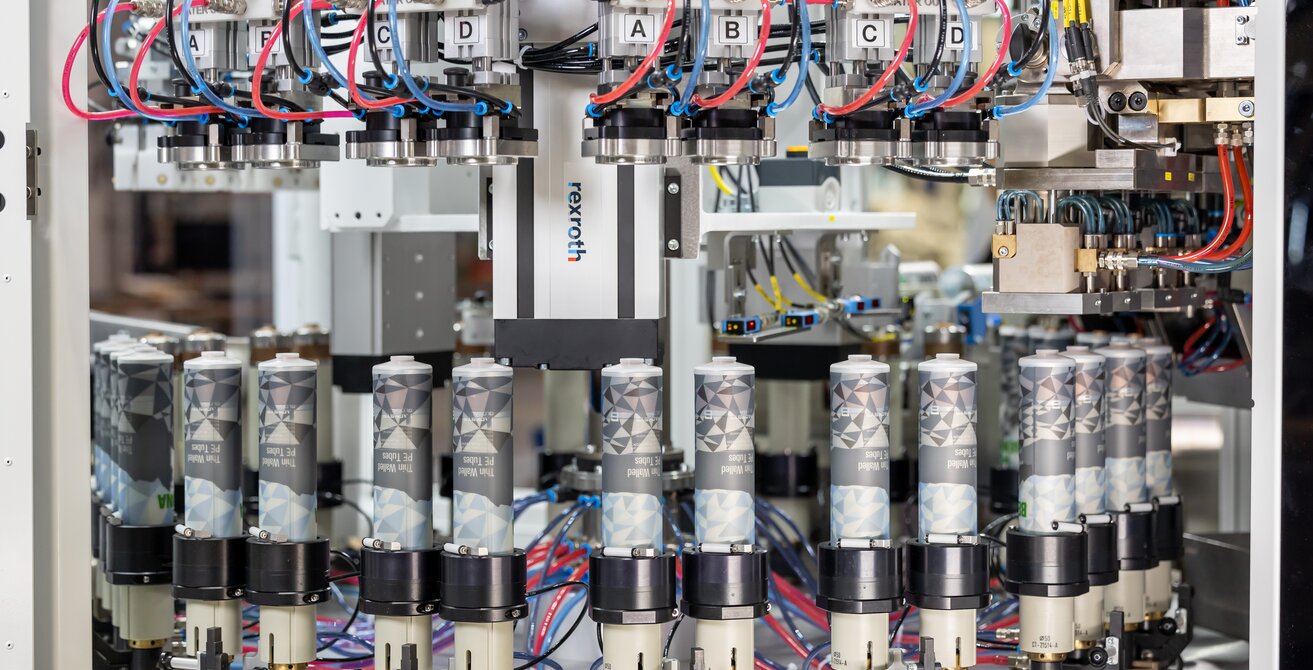

PackSys Global’s installed and commissioned “Twin Decorator” is the answer to these challenges. The Twin Decorator is an intelligent, robust and easy to operate system which reduces print changeover times to as little as 5 minutes. This significantly reduces downtime and increases efficiency by allowing an increased output of between 25-80% depending on the line speed, batch sizes and currently required print changeover times.

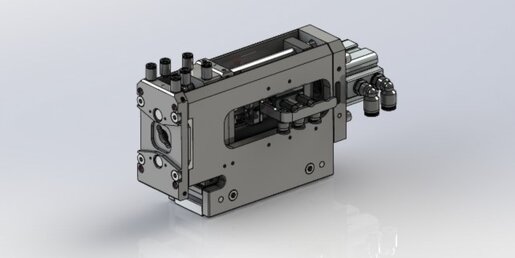

This revolutionary system for monobloc aerosol cans and aluminum tubes uses a second printer, complete with drying oven, connecting the whole system in an intelligent way such that the rest of the line should not need to stop anymore for a print change. Besides the additional decorator, the patented system comprises automatic transfers and bypass systems. These allow a new print job to be set up independently from the actual running batch. Cans are printed and quality can be approved by the QC team before the next batch is started - all this without interrupting customers’ ongoing production.

Applying Twin Decorator technology to existing medium speed aerosol can and aluminum tube production lines allows manufacturers to match the output of new, higher speed lines due to the higher efficiency rates which are the result of largely eliminating print changeover times.