PackSys Global ready for tomorrow's cosmetic market growth

05 Jul 2016

Visitors to K-2016 can see 360° digital printing, new heading and capping systems, a new generation of tube packing machines and hot stamping on the latest equipment from the PackSys Global family of companies.

In a recent report by Allied Market Research, it is predicted that the global cosmetic market will reach US$ 390 billion annually by 2020, that’s a CAGR of 3.7% during 2015-2020. Skin care and hair care products account for 60% of that market. This, coupled with an upsurge in men’s grooming products, foundation, lip balm, concealers, bronzers etc…, spells good news for PackSys Global and its affiliates; Combitool Solutions, Madag Printing Systems and Texa Packaging, since many of these cosmetic care products are produced in plastic or laminate tubes and make-up containers manufactured on our equipment.

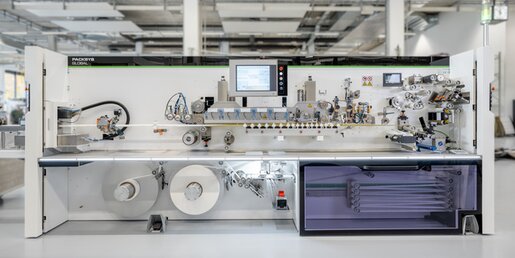

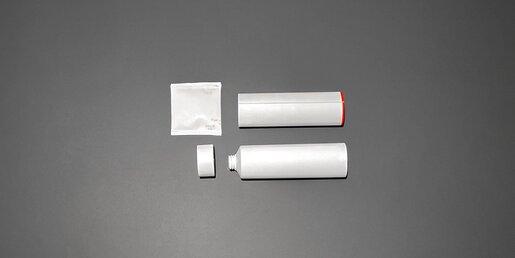

At the 2016 K-show, visitors to booth 3D90 will be able to see demonstrations of an oval cosmetic tube line. Visitors will have the chance to customize partially-printed laminate and watch it being digitally printed before it progresses along the line to become oval tubes, which are then capped and packed into boxes. Also on the booth will be demonstrations of plain closures being hot-stamped and transforming into cosmetic lids we recognize on cosmetic products in the shops.

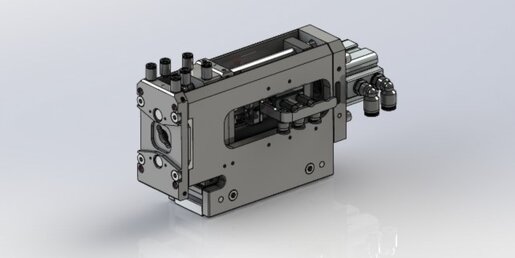

An integrated system from Hapa AG, Combitool Solutions and PackSys Global’s collaboration partner, will digitally print laminate on a PackSys Global laminate tube side-seamer. This technology is perfect for small batch and just-in-time production that is increasingly popular in the cosmetics industry. Digital printing is ideal for special product promotions as well as variable printing and serialization.

Innovative technology and new equipment will then transform the customized printed laminate into a capped oval tube. The processes involved include the popular 360°seam™ seaming technology from PackSys Global. This accurate seaming process is highly attractive to tube producers since it creates laminate tubes with 360° printed appearance in one process step with minimal visible overlap and has dramatically better economies than traditional printing – no labeling required and intelligent laminate structures can be used to produce a thinner tube with the same haptics as an extruded tube.

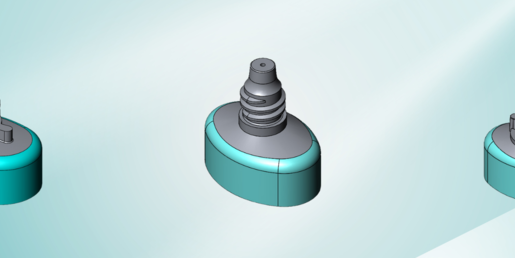

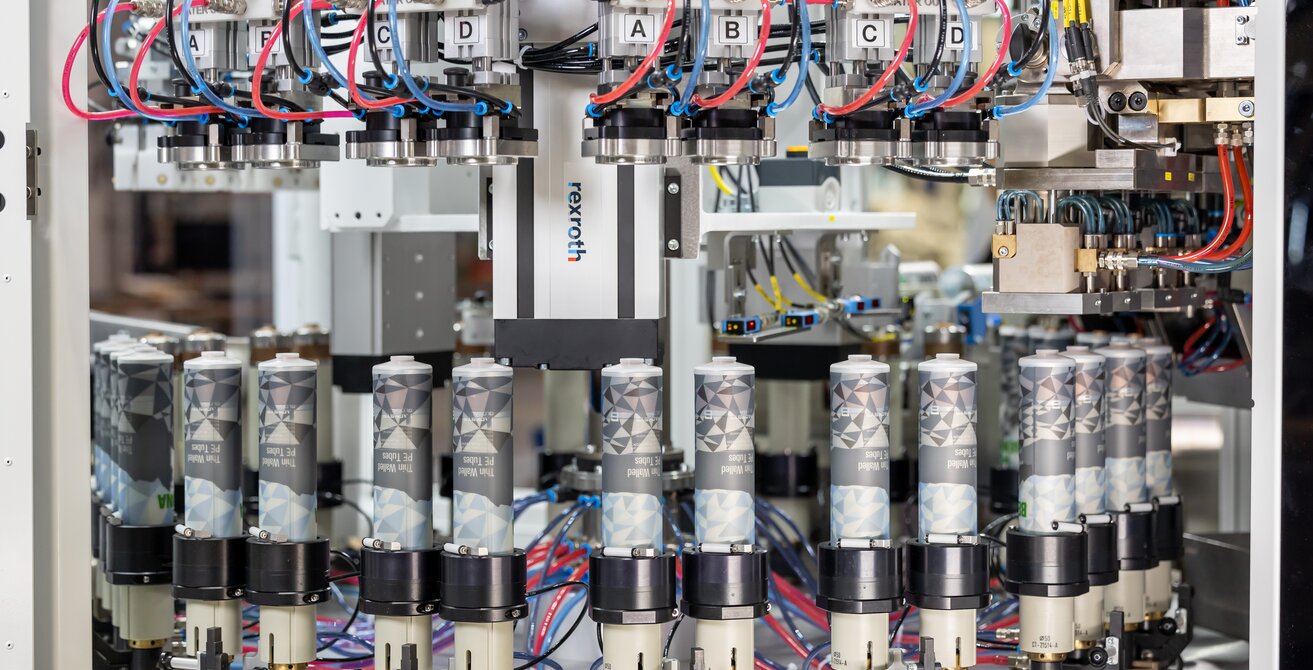

80 capped oval tubes/minute will be produced from the latest equipment from Combitool Solutions. The decorated tubes remain oriented throughout the heading and capping process. The high precision production process allows full production speed from the first tube and all working parameters can be stored and recalled for faster start-up and improved repeatability.

The tubes will then be guided and packed into boxes by a new generation packer from Texa Packaging. This packer is ideal for laminate or plastic tubes and an ideal solution for short, top heavy tubes.

Finally, members of our service team will be on hand to answer questions on our services and present e-Portal, the secure, personalized 24/7 online service platform where customers have access to updated customer documentation: detailed, illustrated product information, and a direct order service for spare parts.