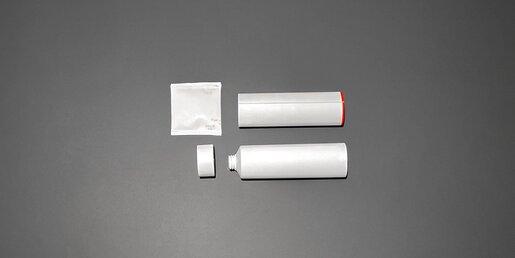

“Tethered” Beverage Container Closures

31 May 2021

New legislation in the European Union requires that by July 2024, all plastic closures must remain “tethered” (attached) to single-use beverage containers after the container is opened. This will bring a big change for the beverage packaging industry. One of PackSys Global’s core competences focuses on the slitting and folding of tamper evident bands. PackSys Global has developed multiple solutions to solve the “tethered” requirements and is ready to answer this demand.

The upcoming European directive, which will be put into effect by July 2024, requires that plastic caps must remain attached to containers during consumption. This means a change to the creation of the tamper evident band. In addition to the protection that customers expect against tampering, closures will need to have even more complex cutting geometry to give both protection against tampering and keep the closure on the package.

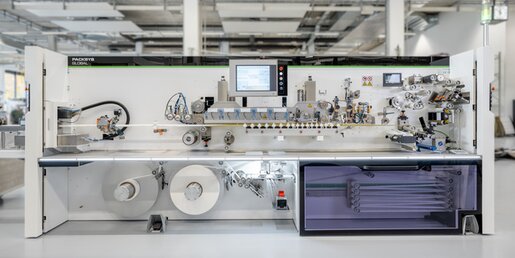

For a long time PackSys Global AG, a world leader for packaging machines, has produced machines which roll the cap along a knife with a specific pressure to create a straight cut around the cap perimeter. Before the EU legislation was enacted PackSys Global was already working on developing slitting solutions which would not only fulfill the regulations but also have a positive impact on our planet. Today a significant amount of plastic closures can be found in our planet’s oceans. The EU legislation is based on the idea recognizes that since there is a high rate of bottle recycling if the closure stays on the bottle the recycling rate for closures should rise and reduce future pollution.

Tethered closure designs need to vary in order to match individual applications and beverage container specifications. To meet the various requirements PackSys Global has designed solutions that can be implemented into existing and new PackSys Global machines. For most applications closure producers do not need to invest in new machines. Consumers can benefit from the protection of traditional tamper evident (TE) closures and help the environment by having the closure “tethered’ as well.

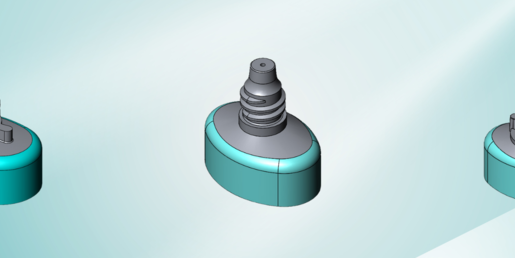

smarTether

A technology with a combination of various cutting segments to create perforation lines for the TE band and the tether function. This can be simple horizontal cutting, or it can be combined with multiple vertical or diagonal slit lines. smarTether purposely leaves a thin and controllable skin in defined sections of the separation lines. It supports in the capping process and will easily break at the first opening. smarTether can be applied on all existing major PET bottle closure applications. The technology delivers a high-performance tethered closure suitable for high-speed capping processes.

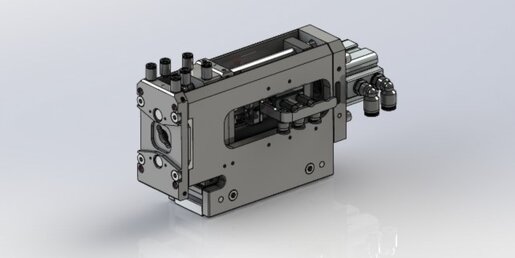

experTether

Lightweight plastic closures require a perfect support of the knives during the slitting process. A continuous support on both sides of the knives is important. experTether and smarTether can both be used for the same cutting line pattern. With experTether the entire slit contour is 100% cut through – including the vertical and diagonal section. This is done by perfect synchronization of the rotating spindles to the fixed slitting knives. Independent of the machine speed, the synchronized inner and outer tooling provide unique slit accuracy for customized slitting patterns for the tethered feature. Both the TE band and the tethered feature are processed on same mechanical cutting technology.

CapCompass

CapCompass is our method to bring a closure, when first opened, to a position which is locked and does not disturb the consumer while they are drinking. Gable top or other carton packaging applications are major markets for this processing method. Whether it’s a pre-molded hinge, the thread start, an embossing, or some other feature, the slit lines can be positioned for functionality and/or marketing purposes. CapCompass is made for cutting closures at the right place and could be combined with smarTether or experTether additionally to TE Band slitting.

Check out our slitting & folding machine portfolio.