Highlights at K 2019

09 Oct 2019

PackSys Global Group at the K 2019 in Düsseldorf

Swiss engineered innovations, performance and reliability

PackSys Global and its subsidiaries Madag Decoration, Combitool Solutions and Texa Packing are proud to present the following highlights at the 2019 K show:

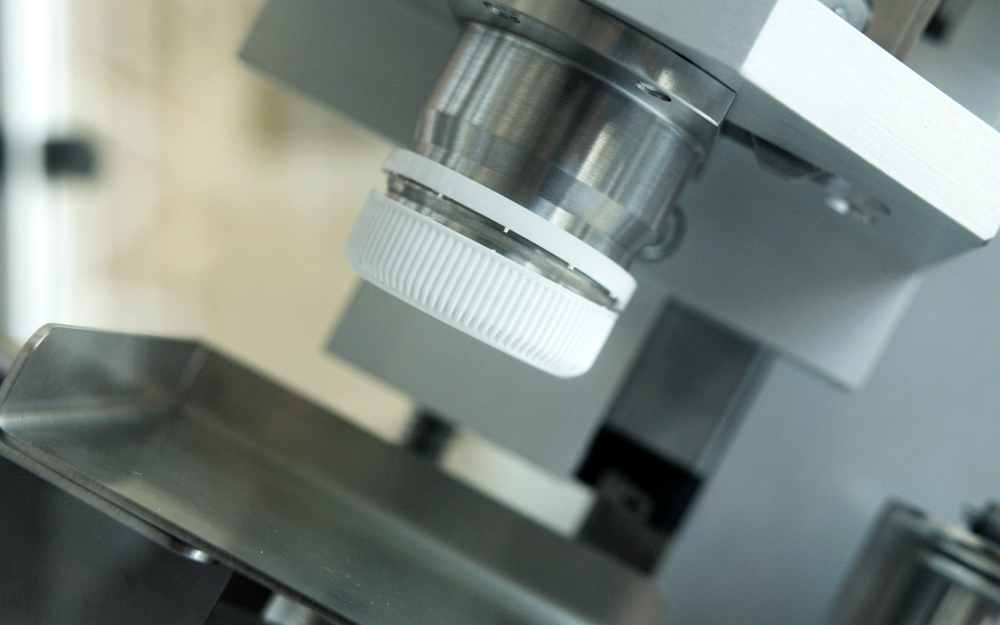

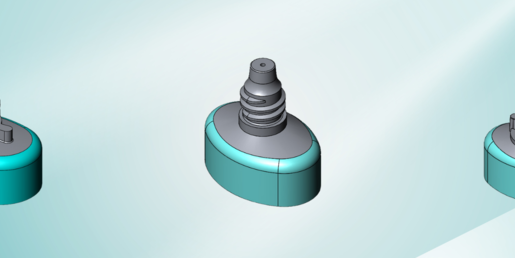

capLAB™

PackSys Global manufactures high speed machines for creating tamper evident bands by folding and slitting plastic caps.

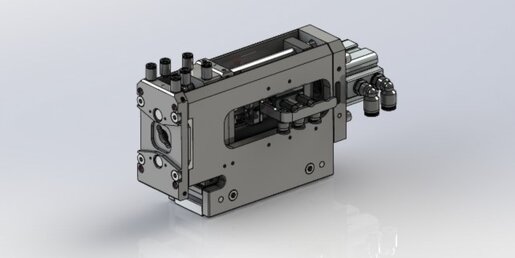

Until now the most important quality control test, known as the pull-off test, which checks the strength and consistency of the tamper evident band, has been done periodically offline in a remote laboratory. PackSys Global has developed and will introduce at the K 2019 “capLAB™”. capLAB™ is the first fully automatic in-line pull -off tester for quality supervision of cap production.

What does capLAB™ do?

capLAB™ can select caps at random or caps which meet specific requirements, for example caps from each cavity on an injection or compression mould or caps which were processed on a specific mandrel on the folding and slitting machine. Because the testing is done on an ongoing basis the time to get the results is measured in seconds. In addition capLAB™ can use the test results to automatically change the settings on the folding and slitting machine so that caps never go outside the approved limits. Because the testing is done automatically capLAB™ helps to reduce labour costs. The lower labour costs can mean that cap production can be performed at a location closer to the site where the caps are applied to the filled bottles, thereby saving transportation costs and emissions from transportation.

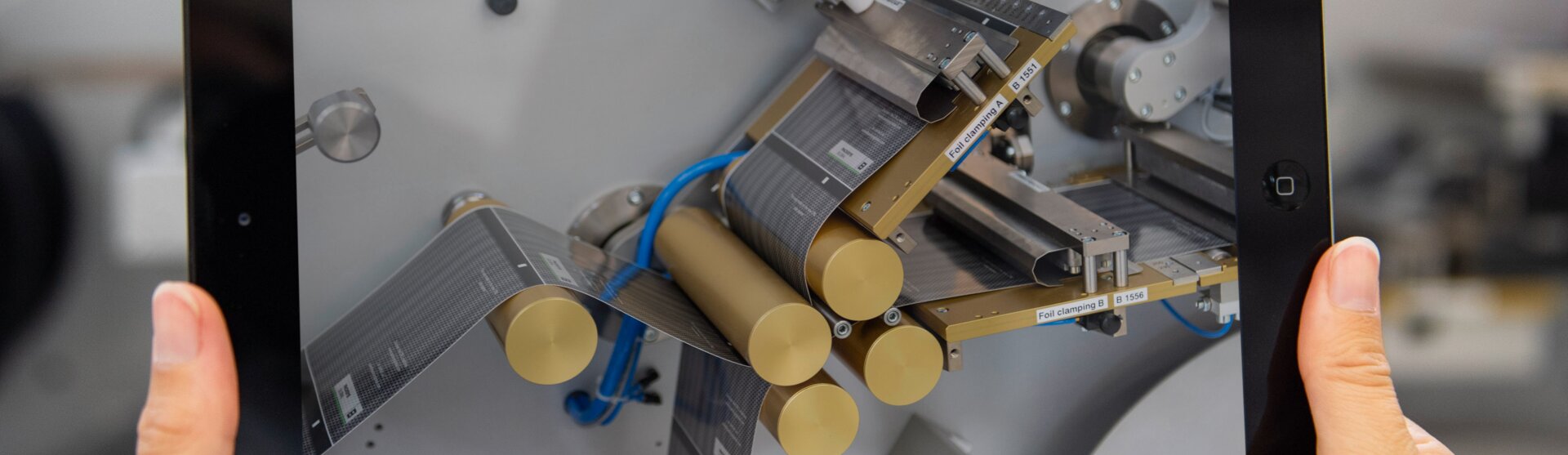

Madag Decoration manufactures hot foil stamping machines for different industries, especially for cosmetics packaging. The machines allow metal foil to be embedded in the packaging in an environmentally friendly process.

A metallized appearance to packaging gives a great effect and makes the product stand out in the shelves. Madag Decoration will present its DecoRoll-XC machine at the K show. The machine is well adapted to the needs of small orders. By using the hot foil stamping technique, the customer can choose between a high-gloss gold and silver appearance or even a brushed or textured look in the product’s packaging. This option is not possible with other techniques.

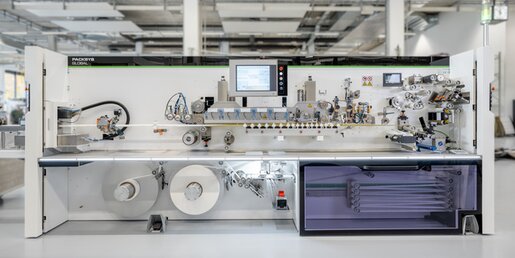

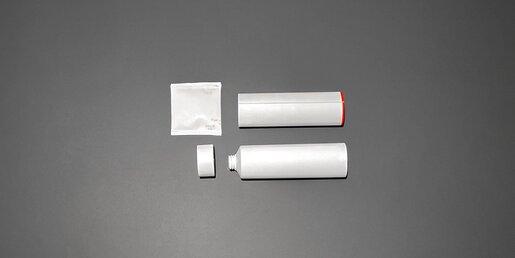

NEOSeam™ is PackSys Global’s new side-seam technology for 360° printed appearance showing no visible overlap to the consumer. This new technique will be demonstrated at the K show on PackSys Global’s LTR2 side-seamer. The NEOSeam™ produces perfectly decorated cosmetic laminate tubes.

At the K Show NEOSeam™ will be combined with PackSys Global’s focus on the use of large diameter tubes to replace extrusion blow molded plastic bottles. Many brand owners use plastic bottles for larger volume packs however these come with an environmental cost. Plastic bottles commonly use between 12 and 40% more plastic than a tube which holds the same volume. PackSys will demonstrate production of 60mm diameter tubes using NEOSeam™ (suitable for pack size of 250ml to 400ml). With the superb aesthetics of NEOSeam™ combined with the substantial weight reduction in plastic, the world can expect to see many products change from bottles to tubes using NEOSeam™ technology.

Combitool Solutions will show its new Prestige 40 tube header and capping machine for plastic or laminated cosmetic tubes at the K show. It is a jewel of innovation designed with a focus on producing weight saving tubes, especially in larger diameters (up to diameter 60mm). The machine provides unbeaten flexibility for today’s and tomorrow’s competitive production environment and challenging market requirements. It ensures high reliability and consistent overall efficiency at an optimal production speed.

At the end of the complete line Texa Packing will present its FlexMaster packing machine will pack the tubes from the Combitool machine into boxes. The grouping technique with mandrel plates and the resulting vertical unloading into boxes makes the FlexMaster an ideal solution for all known packing applications especially including very small diameter tubes (from diameter 10mm), top heavy tubes, oval tubes and short tubes among other challenging requirements.

PackSys Global Group constantly strives to develop customer focused, cost effective and environmentally friendly innovations.

- PackSys Global AG manufactures high-speed machines and complete lines for plastic and laminate tubes as well as folding and slitting machines for plastic beverage caps. Members of PackSys Global are:

- Combitool Solutions, a supplier of machines and tools for manufacturing cosmetic tubes.

- Madag Printing Systems, a specialist for automatic hot foil stamping machines for the packaging, cosmetic and automotive industry

- Texa Packaging, the world’s leading manufacturer of machines that pack unfilled laminate, plastic and aluminium tubes, aluminium aerosol cans, bottles and cartridges.