Fiber Thermoforming: Looks like plastic – made of paper!

13 Jul 2020

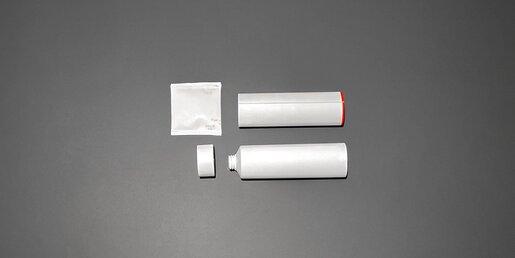

They look as if they were made of plastic: food containers and packaging, medical articles, inlays for mobile phones and other high-quality electronic devices, plant pots, even drinking cups and their lids. But looks can be deceptive. Fiber Thermoforming allows these products to be manufactured from pulp as well as plastic.

The renaissance of cellulose

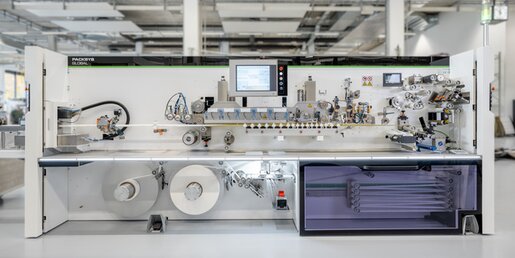

When developing the new Kiefel Fiber Thermoforming machine NATUREFORMER KFT 90, KIEFEL GmbH (Freilassing) made full use of their plastics processing know-how. The result is a machine with a high degree of automation that forms high-quality products from pulp.

Gentle processing

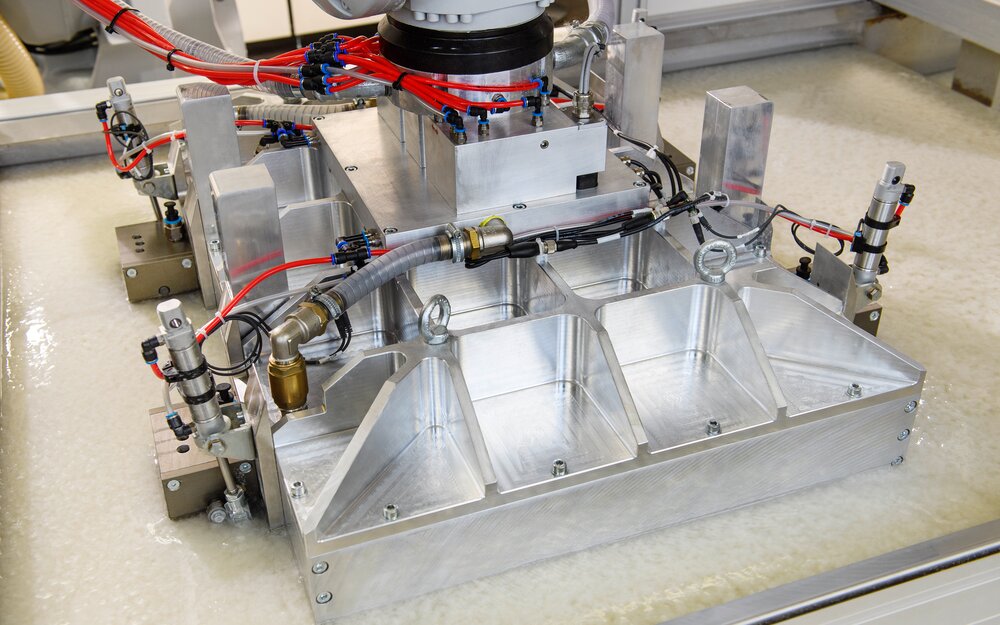

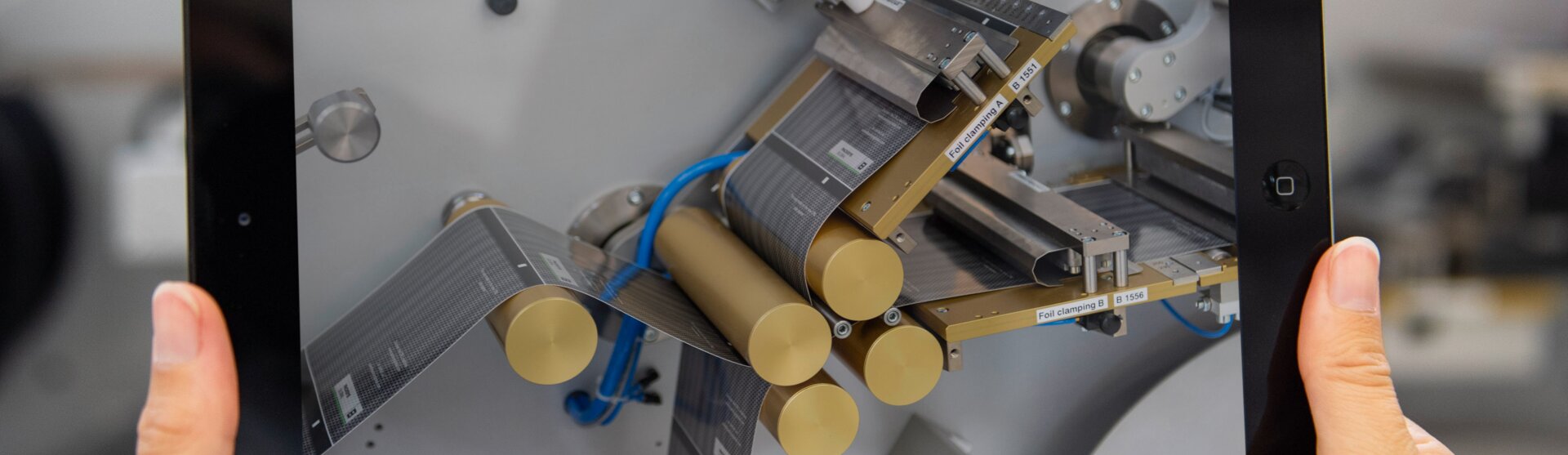

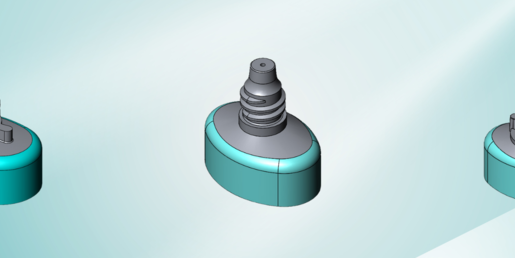

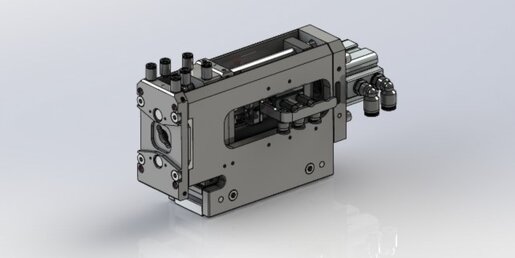

Erwin Wabnig, Head of Fiber Thermoforming at Kiefel describes the capabilities of the process: "The product surfaces of the components made of fresh cellulose on our machines are so brilliant and smooth that only a trained professional can see any difference from plastic products. Depending on the additives, the products can handle hot drinks, hot foods and constant moisture." The performance of the products depends on the additives, the fiber length of the pulp and the process control. The NATUREFORMER KFT 90 forms without damaging the fibers. A suction tool dips into the raw pulp, which is processed in batches. The vacuum applied sucks up liquid and leaves the fibers in the tool, similarly to a filter cake. The suction tool, which is mounted on a robot handling system, then moves into the flexible counter tool of the pre-pressing station. This ensures even fiber distribution across the tool geometry combined with excellent dimensional accuracy. The suction tool then transfers the component to the hot press, where any remaining moisture is eliminated by temperatures up to 200°C in the upper and lower tool and a clamping force of up to 600 kN.

The automation up to the box originates from the plastics thermoforming machines. The machine building company adapts its modules to fulfill the customer's requirements. Testing and inspection systems for quality monitoring can also be integrated if requested by the customer. The NATUREFORMER KFT 90 has an automatic quick-tool change system. The robot system also changes the hot tool within 15 minutes.

Complementary procedure

A broad range of additives mean a lot can be done with cellulose. The attraction of the material is its recyclability. Wabnig describes the current debate: "There is always the question of how much and with which additives I have to modify the pulp so that it fulfills its purpose for the desired application. "Wax, brighteners, pigments, binders - they all affect the recyclability of the products. Therefore, Wabnig is certain: "Pulp will not replace plastic, but complement it. With Fiber Thermoforming, we offer our customers a complementary process to processing plastics, which builds on a lot of experience and process knowledge from our core business." A full scale pilot system of the NATUREFORMER KFT 90 is already operational and producing a reference product at a cycle time of 15 seconds. The first of several machines will be delivered to a customer in the middle of this year.