FAST means FULL SPEED with the new system - FAST PBL

11 Dec 2020

The world is changing rapidly and so is the packaging industry. Many laminate tube manufacturers need to quickly increase their use of mono-material Plastic Barrier Laminates (PBL) to deliver more environmentally responsible and recyclable tubes. This is seen not only in the Oral Care market, which has traditionally heavily relied on non-recyclable Aluminium Barrier Laminates (ABL), but also for the Cosmetics market.

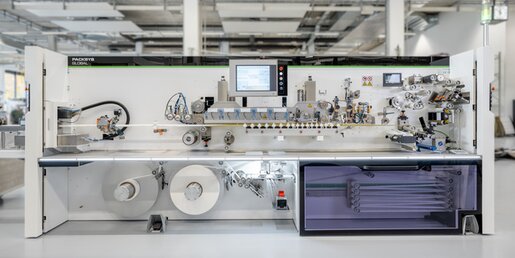

While some tube machines (not the ones from PackSys Global) are not able to make PBL tubes at any speed, many tube machines which can make PBL tubes produce more slowly when using PBL. Producers cannot afford to invest in additional capacity to make up for slow-running machines. The goal has been to make PBL FAST or, as it is now called, FAST PBL.

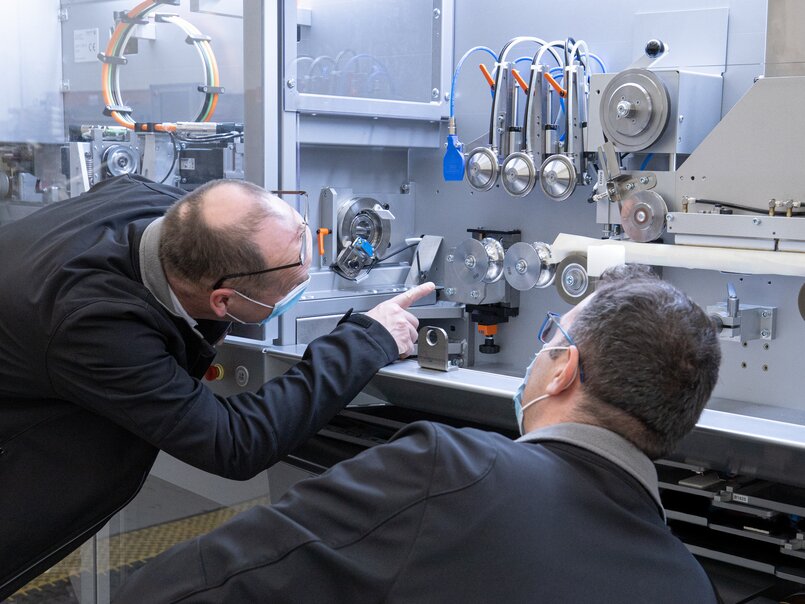

“During this year’s Covid-19 crisis, our Swiss engineers been working hard to invent a new solution to speed up our machines so that there would be no difference in speed between making ABL and PBL tubes. We are pleased to present our innovative solution, which has been developed in only a few months’ time: FAST PBL.

We tested this technology on our 250 tubes/minute LT 250 and most recently achieved a speed of 50 meters/minute, an increase of 50%, which means we can make 250 tubes/minute on every tube length that the LT 250 can make. We are not done yet. Our 500 tubes/minute SHOT line will soon run at 100 meters/minute which would also be a 50% increase. A great result especially when the SHOT line is already the world’s fastest PBL tube making line”, said Julius Läubli, Head of Research and Development of PackSys Global.

FAST PBL is developed considering the requirements for a perfect seam, minimal tube ovality and minimal or no speed reduction. This helps to boost the production of your PBL tubes and achieve the desired line speed.

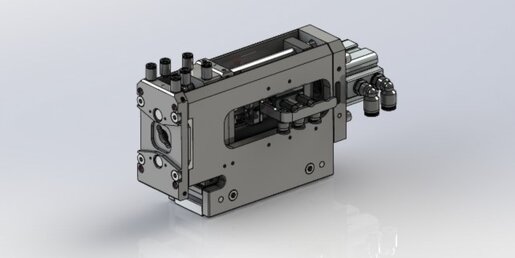

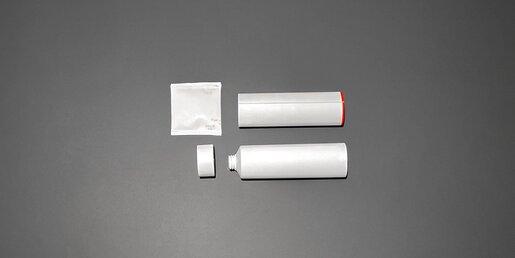

The complete FAST PBL system includes:

- Patented DuraSeam™ air cooling technology

- 2 individually controlled High Frequency (HF) generators

- Latest generation “OCU” (ovality control unit)

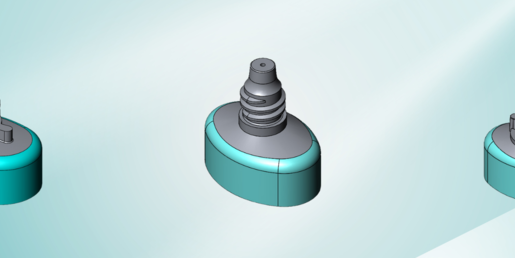

- Innovative mandrel shape known as “Flat Mandrel”

The complete FAST PBL system is easy to implement and more importantly, can be retrofitted on all "continuous" seamers of PackSys Global using HF seaming technology.

Contact

Customer Service of PackSys Global

24/7 Hotline: + 41 55 253 38 38

service@packsysglobal.com

Benefits

- Improved seaming process

- No more speed limitations of running PBL

- Ovality 6% or less when measured 24 hours after production PBL

- Retrofittable on all “continuous” seamers of PackSys Global

- Less operator skill needed