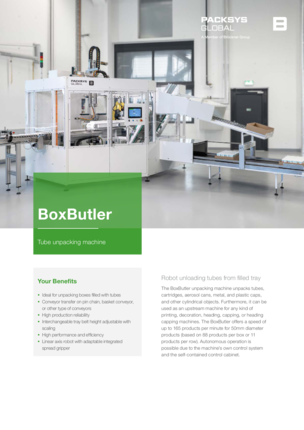

The BoxButler tube unpacking machine

Robot unloading tubes from filled tray

The BoxButler unpacking machine unpacks tubes, cartridges, aerosol cans, metal, and plastic caps, and other cylindrical objects. Furthermore, it can be used as an upstream machine for any kind of printing, decoration, heading, capping, or heading capping machines. The BoxButler offers a speed of up to 165 products per minute for 50mm diameter products (based on 88 products per box or 11 products per row). Autonomous operation is possible due to the machine’s own control system and the self-contained control cabinet.

The steel frame of the machine is adjustable (height) by means of screw supports made of steel/plastic. The box infeed conveyor delivers the boxes to a zero point. Then the box swivel unit places the box in the right position for the unloading robot arm. The BoxButler offers a 6-axis Fanuc robot that places the tubes out of the box on a grouping belt. The included grouping belt (interchangeable tray belt) is driven by a servo motor unit where the height is adjustable with scaling. A linear axis robot with an integrated spread gripper can be adapted to the customer’s conveyor system. The conveyor transfer can be on a pin chain, basket conveyor, or other types of conveyors.

Your Benefits

- Ideal for unpacking boxes filled with tubes

-

Conveyor transfer on pin chain, basket conveyor, or other type of conveyors

-

High production reliability

-

Interchangeable tray belt height adjustable with scaling

-

High performance and efficiency

-

Linear axis robot with adaptable integrated spread gripper

BoxButler Technical Data

| Infeed/Outfeed | According to customer specification |

|---|---|

| Weight | approx. 22,00 kg |

| V=max. | up to 165 products/minute depending on the box orientation and packing style |

| Ø range | 19 - 60 mm |

| Product length | 100 - 230 mm |

| Product style | Round and Oval |

| Box dimensions |

Min: (L × B × H) 300mm × 300mm × 100mm |

| Plastic bag possible | Yes |

| Operating panel | Touch Screen in front door |

| Pneumatic | Festo 9 m3/h at 6 bar |

| Electric | Standard 3 x 400 V ± 5% 50 - 60 Hz TN-S |

How the BoxButler works

The box filled with the product is placed manually through the operator on the machine discharge conveyor. Then, the driven conveyor belt transports the full box to the unloading station. After positioning and gripping the inserted box, the robot unloads the products row by row and puts them in a diameter-related grouping belt. At the same time, a linear robot system with a spreading gripper transports the products to the downstream machine (conveyor or pin chain systems) synchronously and continuously. At the same time, the empty boxes are delivered to an outfeed roller table, where they will be taken away manually by the operator.

BoxButler Video